LOD - Model Progression Specifications:

There are two main BIM LOD Specifications with complement the AIA LOD schema:

There are two main BIM LOD Specifications with complement the AIA LOD schema:

- Document G202™ - 2013 - Building Information Modeling and Digital Data Exhibit. including; Guide, Instructions, and Commentary to the 2013 AIA Digital Practice Documents - Rev. 052213

- BIMForum LOD Specification 2013 - 2016 - Which complements the AIA G202™ - 2013 document.

The AIA has revisited what had become standard terminology within the Building Information Modeling (BIM) industry from the American Institute of Architects (AIA) “Document E202™ - 2008, Building Information Modeling Protocol Exhibit”, and have further developed and modified the former Level of Development definitions.

This revision is only five years since AIA E202 2008 was first published. E202 became one of the most referenced BIM documents irrelevant to the user’s geographic location. Some other groups how tried to create a Level of Development type approach, but have been ignored by the Industry. For a brief history of the original creation of the AIA E202 document, Jim Bedrick ⁹ wrote a good article on AEC bytes back in September 2008 when the document was released. Link here.

If you are unfamiliar with LODs, I suggest you read Antony McPhee's article: "What is this thing called LOD". Please bear in mind some of the definitions have slightly changed since it was written, and these changes are addressed below:

If you are unfamiliar with LODs, I suggest you read Antony McPhee's article: "What is this thing called LOD". Please bear in mind some of the definitions have slightly changed since it was written, and these changes are addressed below:

Let’s review how AIA G202 has evolved, along with some of my own views.

The Guide:

I believe the most important document released along with G202 is the Guide:

I believe the most important document released along with G202 is the Guide:

The revised Guide was re-released in late May 2013. It’s a very lengthy document (62 pages) and elaborates in detail the background and purpose of each clause within E202, G201 & G202. In purely studying Level of Development; I would strongly suggest reading pages 10 – 12 and 46 - 62 (reading it in full is well worth it, just a little time consuming).

How is Level of Development defined?

“Level of Development is the degree to which the element’s geometry and attached information have been thought through – the degree to which project team members may rely on the information when using the model.” ¹

It is a tool to primarily allow the model author to advise model users, what and be relied on; or how much design process and consideration has gone into an aspect of a model element. Provide certainty to model element users.

If, for example, we take a “mechanical supply air duct” within a Model:

If, for example, we take a “mechanical supply air duct” within a Model:

- Can we determine the system route from the modeled duct?

- Do I know where the fire dampers are, so I can locate the access panel?

- Is it sized just using a rule of thumb, or has it undergone airflow calculations to determine the minimum required size?

- Can I determine the duct fixing points from the model?

- Is the equipment the duct is connecting to “Generic” or a specified product?

- Does the modeling include flanges and insulation, for me to determine wall penetration sizes?

These are all valid questions and at different stages through a project, the answer will change. Thus, Level of Development facilitates appropriate use of model elements.

LOD Misconception:

A misconception often is “a model is of “LOD XXX” or “LODs relate to design stages”

“It should also be noted that there is no intended correspondence between Level of Development and traditional design phases. Systems progress at different rates through the design process—for example, design of the structural system is usually ahead of the design of interior construction. At Schematic Design, the model will include many elements at LOD 200, but will also include many at LOD 100, as well as some at 300, and possibly even 400. Similarly, there is no such thing as a “LOD—model”. Models will invariably contain elements at various LODs.”⁵

The Schematic Design (SD) example provided is a little over the top. I would love to hear typical situations where a Sketch Design model would have Elements at LOD 400? The principle is correct. Poor execution in the example.

The Schematic Design (SD) example provided is a little over the top. I would love to hear typical situations where a Sketch Design model would have Elements at LOD 400? The principle is correct. Poor execution in the example.

LOD: No longer Linear

The level of development is no longer identified as a linear progression, that is a scale from LOD100 to LOD200 to LOD300 to LOD400 to LOD500.

The level of development is no longer identified as a linear progression, that is a scale from LOD100 to LOD200 to LOD300 to LOD400 to LOD500.

Item “§ 3.1 Line 2: Each subsequent LOD builds on the previous level and includes all characteristics of previous levels.” ² is now removed for the updated version. LOD100 and LOD500 have also altered to a degree.

When you look closely at the new Level of Development definition wording; “graphically represented” was added. Also, there has been little effort in any of the new documents to truly elaborate on the data behind the different LODs. LOD is primarily talking about the element 3D form.

Simple approach to LODs:

I could re-write them as:

LOD 100: We have data or a symbol for the element, or can determine aspects of the element from its adjacent graphically modeled elements.

LOD 200: We have geometry representing an element type (e.g. a wall) but it is a placeholder. The size and quantities are generated using rules of thumb or educated assumptions.

LOD 300: We have considered the primary functional and spatial aspects of the elements design. Size and Quantities have undergone relevant design calculations or analysis.

LOD 350: We know what manufactured product component the element is, and how it will be mounted and it's connections to relevant systems.

LOD 400: We understand the full shop fabrication and installation requirements. We can generate fabrication level drawings directly from the element geometry.

LOD 500: We have taken the modeled element at the highest former specified LOD within the Model Element Table, checked it against the site installed item and augmented the model to match, maintaining its last specified graphic Level of Development.

Level of Development should never be seen as the design is complete, or “design sign off”. Just because an element is; e.g. LOD 300, does not mean it will not change. We are in a design and construction environment. Design changes, coordination, rationalization, value engineering & preferred construction methods, will all influence the element’s size, shape, location, and orientation. Design sign-off will continue to have the traditional design stage milestone approvals (e.g. Design Development and Construction Documentation). During construction, shop drawing and product/sample sign-off processes will proceed as normal.

Changes to E202 2008:

Model Element Author (MEA) – Definition change:

One of the original shortcomings for the MEA definition was; sometimes the party responsible for an element may not be the party directly modeling it. E.G. Sub-contractors often outsource shop drawing production of their trades; nevertheless, the sub-contractors are the party responsible for coordination of their trade during construction, and not the shop-drawer. Thus the new definition allocated the MEA as the coordinator, and not necessarily the modeler.

One of the original shortcomings for the MEA definition was; sometimes the party responsible for an element may not be the party directly modeling it. E.G. Sub-contractors often outsource shop drawing production of their trades; nevertheless, the sub-contractors are the party responsible for coordination of their trade during construction, and not the shop-drawer. Thus the new definition allocated the MEA as the coordinator, and not necessarily the modeler.

Original: (E202 – 2008) - “1.2.4 The Model Element Author is the party responsible for developing the content of a specific Model Element to the LOD required for a particular place of the Project.”²

Revised: (G202™ - 2013) - “1.4.6 The Model Element Author is the entity (or individual) responsible for managing and coordinating the development of a specific Model Element to the LOD required for an identified Project milestone, regardless of who is responsible for providing the content of the Model Element.” ⁴

The Guide gives this example: “while the structural engineer must be in responsible charge of all the structural engineering on a project, the Architect may be listed as the MEA because they are coordinating the development of the Model Element during the design stages.”⁵ An additional item also added it the words “Individual” as the MEA can be allocated as a specific person within an organization. This provides for greater flexibility, however, if the MEA is only the coordinator, and not the modeler, how is the modelers role and deliverables clearly defined?

Level of Development – Model Content Requirements:

LOD 100 Change:

Original: (E202 – 2008)

“3.2 LOD 100 – Model Content Requirements. Overall building massing indicative of area, height, volume, location, and orientation may be modeled in three dimensions or represented by other data.”²

Revised: (G202™ - 2013)

“2.2 LOD 100 – Model Element Content Requirements. The Model Element may be graphically represented in the Model with a symbol or other generic representation, but does not satisfy the requirements for LOD 200. Information related to the Model Element (i.e. cost per square foot, tonnage of HVAC, etc.) can be derived from other Model Elements.”³

This new definition is substantially different from the old one. LOD 100 was originally an allocation for the overall building mass or potentially building data (e.g. building briefing program) and was the only LOD not element specific. The new approach opens up the use of LOD 100 that on an element level anything not meeting LOD 200 criteria can be defined as LOD 100.

“At LOD 100, Model Elements are in the form of narratives, program information, etc. An LOD 100 Model Element is not geometrically modeled, but may be included in a Model as a symbol that does not represent actual geometry. It is also possible that the Model Element is not individually represented in the Model in any graphical sense, but its existence can be derived from other Model Elements that are graphically represented in the Model. For example, the existence of a mechanical system can be derived from the square foot quantity associated with the floor slab that is represented in the Model at LOD 200. LOD 100 elements are extremely useful early in the design process. They enable the designer to embed a great deal of intelligence regarding such things as approximate costs and system capacities in a Model consisting of nothing more than floors, and then to quickly derive overall costs and capacities as the Model is changed. Some Model Elements may remain at LOD 100 through to the end of the Project.”⁵

An example of this may be door furniture. Door Furniture (hardware) is rarely modeled; nevertheless the specific information on door furniture may be attributed to the door.

I believe the G202 definition of LOD 100 is very confusing. It mixes graphical data not meeting LOD 200 requirements, with attached attribute data to model elements which may, or may not be of a higher LOD. Separating out graphical and non-graphical data is far simpler in specifying model element progression.

I believe the G202 definition of LOD 100 is very confusing. It mixes graphical data not meeting LOD 200 requirements, with attached attribute data to model elements which may, or may not be of a higher LOD. Separating out graphical and non-graphical data is far simpler in specifying model element progression.

LOD 200 Change:

Original: (E202 – 2008)

“3.3 LOD 200 - Model Element Content Requirements. Model Elements are modeled as generalized systems or assemblies with approximate – quantities, size, shape, location, and orientation. Non-geometric information may also be attached to Model Elements.”²

Revised: (G202™ - 2013)

“2.3 LOD 200 – Model Element Content Requirements. The Model Element is graphically represented within the Model as a generic system, object, or assembly with approximate quantities, size, shape, location, and orientation. Non-graphic information may also be attached to the Model Element.”³

“In general, LOD 200 elements are generic placeholders. This is the lowest level at which a geometric representation of a Model Element will appear.”⁵ Its worth emphasizing the use of the word approximate. Thus, it is anticipated elements at LOD 200 will change in size, location, shape orientation and quantities in its development to LOD 300. The word “object” has also been added. Not every element required for the building will require the assembling of multiple parts. Elements which “may” not progress beyond LOD 200 in the design model may include:

- elements within a future phase

- elements outside of the scope of the MEA, but are required for context in the model / design

- elements for “potential” temporary works

- elements that may be further developed by a specialist sub-contractor

- elements determined to be documented & coordinated primarily from 2D or written documentation

You may have noticed the LOD definitions LOD 200 to LOD 500 has changed from “Model Elements” to “Model Element”. This emphasis LOD is on a specific Element basis. Too often you hear people ask “What LOD is the model at?” The fact is, the elements across the model are going to be at various LODs.

LOD 300 Change:

Original: (E202 – 2008)

“3.4 LOD 300 - Model Element Content Requirements. Model Elements are modeled as specific assemblies accurate in terms of quantity, size, shape, location, and orientation. Non-geometric information may also be attached to Model Elements”²

Revised: (G202™ - 2013)

“2.4 LOD 300 – Model Element Content Requirements. The Model Element is graphically represented within the Model as a specific system, object or assembly in terms of quantity, size, shape, location, and orientation. Non-graphic information may also be attached to the Model Element.”³

The interesting item here is; the word “accurate” has been removed from LOD 300. The wording “accurate”, is not used until LOD 400. Some opinions I came across, suggested at LOD 300, the MEA knows the exact specified product. This often led to building service consultants creating a LOD 250 definition; as there equipment was generic (i.e. manufactured product unspecified). This update and some other items later in the definitions have helped clarify this situation, however it still requires better clarity.

“LOD 300 Model Elements are specific assemblies, such as specific wall types, engineered structural members, system components, etc. The design of the Model Element is developed in terms of composition, size, shape, location and orientation. Construct-ability and coordination of other building components may require change to some Model Elements after they are designated LOD 300, but such changes should be minimized as much as possible.”⁵

“A Model that is developed sufficiently to derive traditional construction documents will appropriately include Model Elements with Levels of Development ranging from 100 to 300. Level of Development defines, most importantly, the maximum reliance that a designated user may place upon a given Model Element. ”⁵

LOD 350 Addition:

On BIM projects it is common practice for the sub-contractors to use design software (and not fabrication software) to create their initial models. This often helps interoperability with the design consultants and “some” fabrication software, which do not yet have good analysis or data exchange capabilities. Typically for these models, the sub-contractor knows the exact product to be installed and is interested in a high level coordination, including mounting and fixing coordination. The LOD Specification has created a new LOD 350 to accommodate this.

On BIM projects it is common practice for the sub-contractors to use design software (and not fabrication software) to create their initial models. This often helps interoperability with the design consultants and “some” fabrication software, which do not yet have good analysis or data exchange capabilities. Typically for these models, the sub-contractor knows the exact product to be installed and is interested in a high level coordination, including mounting and fixing coordination. The LOD Specification has created a new LOD 350 to accommodate this.

BIMForum LOD Specification

“LOD 350. The Model Element is graphically represented within the Model as a specific system, object, or assembly in terms of quantity, size, shape, orientation, and interfaces with other building systems. Non-graphic information may also be attached to the Model Element.”¹

“LOD 350. The Model Element is graphically represented within the Model as a specific system, object, or assembly in terms of quantity, size, shape, orientation, and interfaces with other building systems. Non-graphic information may also be attached to the Model Element.”¹

“At LOD 350 enough detail for installation and cross-trade coordination is included. For the wall example, this would include such things as blocking, king studs, seismic bracing, etc.”¹

LOD 400 Change:

Original: (E202 – 2008)

“3.5 LOD 400 - Model Element Content Requirements. Model Elements are modeled as specific assemblies that are accurate in terms of size, shape, location, quantity, and orientation with complete fabrication, assembly, and detailing information. Non-geometric information may also be attached to Model Elements.”²

Revised: (G202™ - 2013)

“2.5 LOD 400 - Model Element Content Requirements. The Model Element is graphically represented within the Model as a specific system, object or assembly in terms of size, shape, location, quantity, and orientation with detailing, fabrication, assembly, and installation information. Non-graphic information may also be attached to the Model Element.”³

“2.5 LOD 400 - Model Element Content Requirements. The Model Element is graphically represented within the Model as a specific system, object or assembly in terms of size, shape, location, quantity, and orientation with detailing, fabrication, assembly, and installation information. Non-graphic information may also be attached to the Model Element.”³

It is only special fabrication elements that should be allocated LOD 400 (“fabrication, as the term is used here, refers to project‐specific fabrication rather than manufacture of standard components.”⁵). Steel members, metal work, precast concrete panels and duct work will all be custom orders for the building and LOD 400 may be specified for these elements. VAV boxes, Chillers, Plumbing Fixtures, etc, are likely to be all specified products, and thus a LOD 400 modelling is not required. “A Model Element qualifies as LOD 400 once all information necessary for fabrication and installation has been resolved.”⁵ “Only selected Model Elements requiring significant detail will be taken to LOD 400.”⁵

LOD 500 Change:

Original: (E202 – 2008)

“3.6 LOD 500 - Model Element Content Requirements. Model Elements are modeled as constructed assemblies actual and accurate in terms of size, shape, location, quantity, and orientation. Non-geometric information may also be attached to modeled elements.”²

Draft Revised: (G202™ - 2012)

“2.6 LOD 500 - Model Element Content Requirements. The Model Element is a field verified representation in terms of size, shape, location, quantity, and orientation. Non-graphic information may also be attached to the Model Elements.”³

“The LOD 500 filed verified representation may be viewed as an “as‐built Model. When an as‐built Model is required, obviously not every aspect of the Project is field verified. LOD 500 provides for specific indication of which elements will be field verified. This allows the owner to be clear on what is and is not verified, and allows whoever is responsible for producing the as‐built Model to determine and price the effort involved.”⁵

An aspect of LOD 500 I find challenging and generally confusing; “It does not tell you the design/construction LOD, or the Level of Detail the element reached”. “Model data that in an earlier LOD indicated optional selections is replaced by the final installed choice.”⁵ “Model Elements do not necessarily need to be brought up to LOD 400 before going to LOD 500. Likewise, not all Model Elements will be developed to be LOD 500 in order to be appropriate for the as‐built Model. A Model Element representing paint might never be developed beyond LOD 100, but the owner may want the color field verified in certain areas.”⁵

“Simply stated, a Project milestone called "record model," would consist of a mixture of Model Elements at LOD 100, 200, 300 and 400 that are not field verified and a mixture of LOD 500 Model Elements that have been field verified. The Project milestone of a "Record Model" is an imperfect activity, not unlike a "Record Drawing," as it represents the level agreed to by the Owner, Architect, and Contractor as to the appropriate amount of effort for recording and investigating a Model that is prudent for the Owner’s use of the Model after construction.” ⁵

Personally, I think the above is contradictory of the of the LOD 500 definition. I believe the approach in the guide is the correct approach, but that should mean the definition should be written as:

LOD 500 - Model Element Content Requirements. The Model Element maintains the same graphic representation as its highest former specified LOD within the Model Element Table, with the addition of it being field verified.

I believe the approach similar to the standard BS 1192 Part 1 – 2007 of changing the Model Element status to “AB” (As-Built) or similar would be clearer for users to understand its actual graphical representation. It also needs to be taken into account; many owners don’t require a graphical representation level of LOD 350 / LOD 400 for As-builts. It’s just to detailed, and it can also not be practical.

“Field Verified” as a term can be viewed in a few different ways. It is a considerable improvement from “As-built”, that has been used for 2D post-construction client requests. Traditionally “As Builts” generally was understood to mean: the consultant's construction drawings are updated to include any Architectural or Consultant instruction/advice notices which occurred during construction. PAS 1192. Part 2 2013 has come up with its own definitions:

“As-built” is defined as the record drawings and documentation defining deviation to the designed information occurring during construction at the end of the project.”⁶

“As-constructed” defines the defect and deviation to the designed model occurring during construction.

The “as-constructed” model and its appended documentation are continually updated through re-measurement as construction progresses. This allows for deviation to be reviewed with respect to the following packages and making knowledgeable assessment of impact and resolution.”⁶

There is no indication of element geometry accuracy with-in LOD 500. This is actually a good thing, as getting down into + or - tolerances for as-builds may be a mine field. It will vary from project to project and element to element. Some possible examples:

- · “Asset Management”, requires the asset is modeled in the correct Space/Room with approximate location (± 250mm is generally satisfactory).

- · “Retail Space Management”, Tenant party walls will require accuracy to the nearest ±20mm, as the space area will directly affect tenant rental costs.

Between major building redevelopment works, there are several minor subtle works that are carried out on buildings, many of which don’t undergo any drawings, not alone modeling development. Buildings also naturally move and settle. From an operations, health and safety (OH&S) stand point, carrying out new works without a recent survey, entails a high degree of risk. Thus before major re-development works take place, there is always need for some verification of existing conditions.

Authorized Use:

The LOD element Authorized Uses have also undergone some minor updates from E202-2008 to G202-2013. I am often surprised on looking through BIM Management Plans that use LOD Model Element Content Requirements, many leave out the Authorized Uses. These are an integral part of how models may be used. The G202 2013 guide, recommends: “Document users should modify and revise the Authorized Uses to fit their particular needs.”⁵.

It is not practical for every model released with elements of LOD “XXX”, that it will be appropriate for "all" Authorized Uses. Thus, I view model “Authorized Uses” as a model issue status, i.e.

- “Issue for Coordination”

- “Issue for Costing”

- “Issue for Time Sequencing”

- “Issue for “X” Analysis”

- “Issue for Digital Set-out (Layout) point identification”

- “Issue for the generation of construction/fabrication models”

For weekly or bi-monthly model issues, they typically have the status of “Issued for Coordination”. It may be used for general review and comments or clash detection coordination. Many of the other “Authorized Uses” only come up at specific project mile-stones, and it should be anticipated the model author will carry out specific Q.A. checks, before the model is released for that purpose.

Matrix Tables:

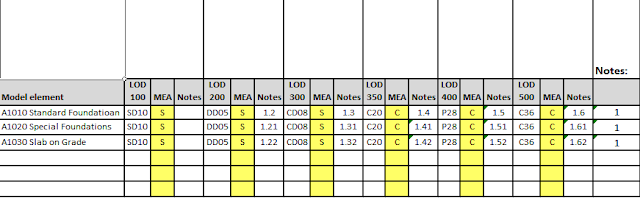

G202 2013 has further expanded the Model Element Table to have a notes section for each column. This allows for greater flexibility, and this approach started to appear in the industry, even before the release of G202.

Above: Extract from: 4.3 Model Element Table: “AIA Document E202™ – 2008” ²

Above: Extract from: 4.3 Model Element Table: “AIA Document G203™ – 2013”³

The Guide for G202, suggests the Model Element Table may be customized to meet project and user needs. “The Model Element Table is intended to be flexible and each Project will have its own unique requirements to identify the Model Element Author. If the table is used within a small firm, employee initials or indication of the consulting firm may be all that is needed. With greater complexity, other indications can be used.”⁵ The table does not need to follow CSI UniFormat, nevertheless it recommends using an official classification system, primarily to ensure all element types are listed. Items outside the scope of Modelling may be allocated “NM” (Not Modeled). Previously, I had created a section with-in BIM Management Plans for “Not Modeled” or “Partial modeling”. I believe, either way, will allow the flexibility to elaborate what is not included in the model.

Project Mile-Stones:

In following the approach by G202-2013, it associates a model element LOD status at the point of a project mile-stone. I have always had issues with this, as it is not practical to say several different element types, on the mile-stone date, suddenly be the new LOD status. The table to work effectively needs to link closely to the project program. The second primary purpose of the table is: “To coordinate between disciplines: to give the Project team an overview of who needs to provide what information at what time in order to meet milestones.”⁵ Some examples:

- The Architect must identify the number and location of Plumbing fixtures before the Hydraulic Engineer can begin their design. So the Plumbing Fixtures (in the Architectural Model) LOD 200 deadline may be 6 weeks before design stage milestone.

- Costings typically occur during the last two weeks (approximate) of some design mile-stones. Thus model elements of the specified Level of Development need to develop some time before the Costing starts.

- During Construction, there are several shop drawing review deadlines required in order to meet the construction program. There are just not enough columns (6 Number) for each of these deadlines in the G202-2013 table.

Thus, I find it beneficial to specify a specific Stage Week Number or percentage. e.g.:

- Design Development: Week No. 6 of 12 = 50%DD

- Construction: Steel Shop Drawing Reviews, Week No. 6 of 8 = 75%SSDR,

Below, is an example of my approach to the Model Element Table. The difference being, it specifies the LOD (Level of Development) in the header, and the delivery time in the column.

Above: Example of custom Model Element Table.

When assessing to fill out a Model Element Table, it is not anticipated all information can be completed in a single sitting. Detailed information for LOD 350, LOD 400 and LOD 500, may only be available when the relevant MEA responsible parties are engaged.

BIMForum LOD Specification

This document builds on the development of AIA G202 2013, to assist in further defining expectations. It follows the CSI UniFormat classification system, and provides graphical imagery where relevant. It again focuses on the element geometry: “the specifications were developed to address model element geometry, with three of the most common uses in mind – quantity take-off, 3D coordination and 3D control and planning.” ¹

Extract from Level of Development Specification – 2013 – BIMForum - B1010.10 – Floor Structural Frame¹

Below; another example for the “BIMForun LOD Specification 2013”

“D3050.50 – HVAC Air Distribution

LOD 100 - Generic elements or quantitative call outs; conceptual and/or schematic flow diagrams; minimal design performance information.

LOD 200 - Generic elements; schematic layout with approximate size/shape/location of mains and risers; design performance Information; shaft requirements represented in the model

LOD 300 - Specific elements; modeled as design specified elements specified size/shape/spacing/location of duct/dampers/fittings/insulation for risers/mains/branches; approximate allowances for spacing and clearances required for all specified hangers, supports, vibration and seismic control that are to be utilized in the layout of all risers/mains/branches; actual access/code clearance requirements represented in the model

LOD 350 - Detailed elements; modeled as contractor submitted actual elements actual size/shape/spacing/location/connections of duct/dampers/fittings/insulation for risers/mains/branches; actual size/shape/spacing/clearances required for all hangers, supports, vibration and seismic control that are utilized in the layout of all risers/mains/branches; actual floor and wall penetrations required represented in the model

LOD 400 - Manufacturer or Contractor elements added to the model required for fabrication and field installation”¹

I hope it is taken up by the construction industry. I always believe if an industry standard system exists, which is workable, it should be utilized. There is no reason if an item within the document is disputed when filling out the Model Element Table, it can be manually amended or struck-out for the specific project.

The BIMForum LOD Specification is now in its 2015 release. Refer here for more information.

The BIMForum LOD Specification is now in its 2015 release. Refer here for more information.

Information Modelling:

You may see the above LOD’s has no specified Information or Data attributed to the model. Anywhere it mentions information is uses the word “may”. If we are in a “BIM” environment, and thus exchange reliable attributed model data, a separate section of the BIM Management plan will need to include this.

This may be as detailed as the COBieResponsibility Matrix ⁷.

Or a simpler approach as in the New York City, Department of Design + Construction. BIM Guidelines ⁸. What ever method works best for the project deliverable.

The thing about data is, it is very different for each project. I don’t believe it can be easily standardised. The above example does allow for a custom approached. At a minimum, you would hope any items “Tagged” in the paper documentation; contain the relevant tag attribute data in the model element. Whatever the approach, it will require clarification and is maybe better off kept separate from LOD’s.

Close:

The developments of G202 (incl. the guide) and the Level of Development Specification have greatly clarified the intended use of LOD’s. I see the next step is the education within the industry. The definitions have moved on considerably from AIA E202 2008, and even with for former definitions, there have been many variations in people’s perception of what they were.

The developments of G202 (incl. the guide) and the Level of Development Specification have greatly clarified the intended use of LOD’s. I see the next step is the education within the industry. The definitions have moved on considerably from AIA E202 2008, and even with for former definitions, there have been many variations in people’s perception of what they were.

Finally in closing out I see that Collaborate ANZ are just about to develop LOD’s further for the Australian and New-Zealand regions. It should be interesting to see what they come up with. Final Collaborate ANZ outcome here.

Other LOD articles you may find interesting:

A Review - BIMForum LOD Specification-2015 - A review on the 2015 BIMForum LOD Draft Specification (Released April 2015). What works and what doesn't. How to make the document work for you. This review has been updated to reflect the final November 2015 Release.

As-Built BIM: LOD 500 under the Microscope: Does the LOD 500 framework give clarity to the project team. This article proposes a new alternative to meet client and project teams needs.

LOD – the biggest BIM con to date! - Reviews the primes that the AIA G202 Level of Development is built on, and suggest its time to develop at Model Progression Specification that works with the project,

Other LOD articles you may find interesting:

A Review - BIMForum LOD Specification-2015 - A review on the 2015 BIMForum LOD Draft Specification (Released April 2015). What works and what doesn't. How to make the document work for you. This review has been updated to reflect the final November 2015 Release.

As-Built BIM: LOD 500 under the Microscope: Does the LOD 500 framework give clarity to the project team. This article proposes a new alternative to meet client and project teams needs.

LOD – the biggest BIM con to date! - Reviews the primes that the AIA G202 Level of Development is built on, and suggest its time to develop at Model Progression Specification that works with the project,

References:

² AIA Document E202™ - 2008 Building Information Modeling Protocol Exhibit

³ AIA Draft Document G202™ - 2013 -Building Information Modeling Protocol Exhibit

⁴ AIA Draft Document E203™ - 2013 -Building Information Modeling and Digital Data Exhibit

³ AIA Draft Document G202™ - 2013 -Building Information Modeling Protocol Exhibit

⁴ AIA Draft Document E203™ - 2013 -Building Information Modeling and Digital Data Exhibit

⁶ PAS 1192-2: 2013 Incorporating Corrigendum No. 1, Specification for information management for the capital/delivery phase of construction projects using building information modelling

Some other good resources:

No comments:

Post a Comment

Please partake in the discussion. We welcome all feedback and comments, however spam will be removed from the comments section.